What is the DX initiative that does not fail in the manufacturing industry and Thailand? Explaining issues and solutions together

![]() 04-Sep-2022

04-Sep-2022 ![]() 04-Sep-2022

04-Sep-2022

Table of contents ∇

1 What is DX?

2 DX status of Japanese companies overseas

2.1 28% are working on DX

2.2 Two issues that come to mind

2.2.1 More than 60% of companies have not introduced DX

2.2.2 Some companies have already introduced DX, but have not been able to realize the results

3 Issues faced by companies

3.1 Issue①「Human resources」

3.2 Issue②「Cost」

3.3 Issue③「Information/Knowledge」

3.4 Issue④「Internal understanding」

4 Solutions to challenges

4.1 Solution①「Hybrid utilization of internal and external human resources」

4.2 Solution②「Scale up from small start」

4.3 Solution③「Participation in external seminars and advice at spots」

4.4 Solution④「Top-down overall optimization」

5 Summary: In order not to fail in DX in the manufacturing industry and Thailand

What is DX?

DX is an abbreviation for Digital Transformation, and it is a hypothesis that “The penetration of IT will change people’s lives for the better in every aspect.” It is said to have been proposed by Eric Stolterman, a professor at Umeå University in Sweden.

The Ministry of Economy, Trade and Industry’s “DX Recommended Guidelines” defines DX as follows.

“Companies can respond to drastic changes in the business environment, utilize data and digital technology, and transform their products, services, and business models based on the needs of customers and society. To transform our culture and climate and establish a competitive advantage.”

In the past, the goal and purpose was to “Improve business efficiency” by utilizing IT and digital technology, but now there is a change in the purpose of “reforming business models and organizations.”

DX status of Japanese companies overseas

Solution①「Hybrid utilization of internal and external human resources」

DXに取り組んでいるのは28%

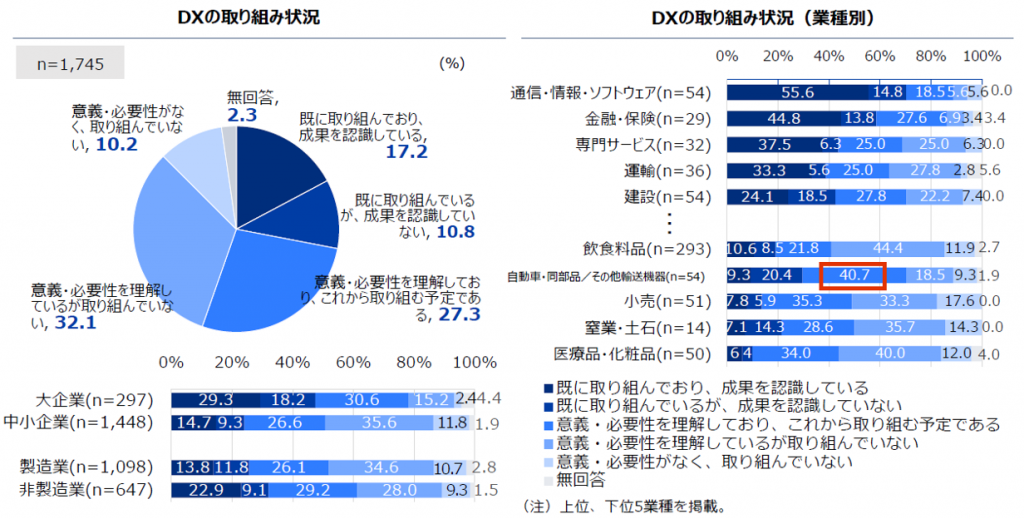

This is the result of a questionnaire survey conducted by JETRO from early November to early December 2021 targeting Japanese companies that are highly interested in overseas business, and received responses from 1,745 companies.

When we took a questionnaire about the status of DX initiatives, only about 30% of the 28% of companies who answered that they were already working on it.

By industry, “Communication/Information/Software” had the highest rate of “already working” at 70.4% of the total.

On the other hand, 29.7% of the companies in the “automobiles/automotive parts/other transportation equipment” sector, where many companies have expanded into Thailand, answered “yes” to this question, which is close to the industry average. rate is obtained.

Two issues that come to mind

According to the results of the questionnaire survey, nearly 60% of companies in the industry as a whole responded that they “understand the significance and necessity of DX in overseas expansion, but are not working on it at this stage.” I’m here. In the same question, if we focus only on the manufacturing industry, it is 60.7%, exceeding the average for the industry as a whole.

It seems that the necessity of DX is understood, but it can be read that the majority of companies have not been able to move to the implementation stage.

On the other hand, 10.8% of the companies that responded that they had already introduced DX said they were not aware of the results.

In the category of “automobiles/automotive parts/other transportation equipment,” where many companies have expanded into Thailand, the percentage was 20.4%, exceeding the percentage of “companies that are realizing results.”

It can be seen that most of the people who have spent time and money to convert to DX have not obtained satisfactory results.

Issues faced by companies

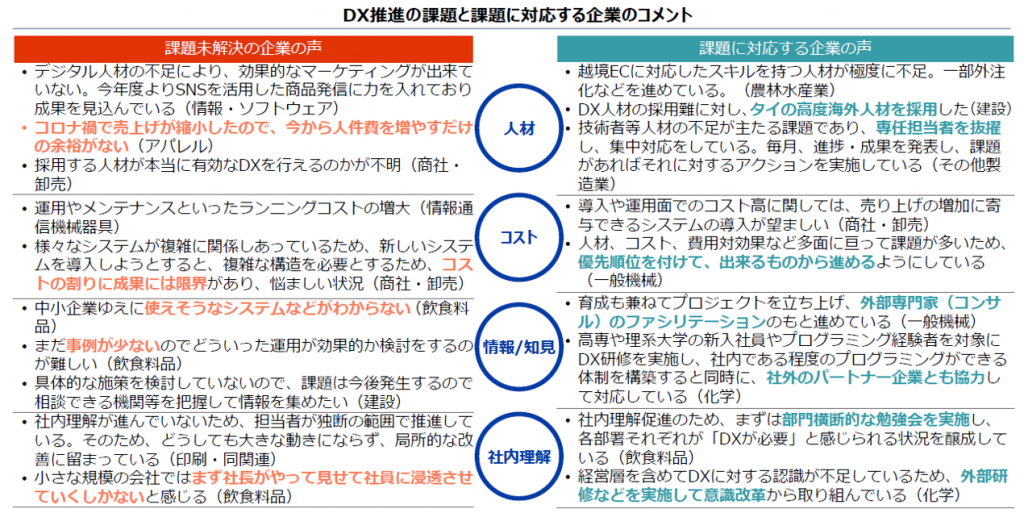

・Effective marketing is not possible due to the lack of digital human resources. From this fiscal year, we have been focusing on disseminating products using SNS, and we expect results (Information/software).

・Since sales have shrunk due to the corona crisis, there is no room to increase labor costs from now on (Apparel)

There is a shortage of digital human resources, and it seems that each company is struggling to acquire human resources. In addition, it seems that it is a source of trouble that the skills of the human resources to be hired are unknown, so they can not take drastic recruitment activities.

In addition, it seems that we are in a dilemma where we want to proceed with DX, but we cannot proceed, such as the fact that we cannot secure human resources to promote DX, due to the impact of our main business due to declining sales and soaring labor costs.

・Increased running costs such as operation and maintenance (information communication equipment)

・Because various systems are intricately related, when trying to introduce a new system, a complicated structure is required, so the results are limited in relation to the cost, which is a troublesome situation (trading company, wholesale)

I get the impression that the effects of the investment have not been efficiently recovered, such as the increase in running costs due to the introduction of the system, and the increase in functions due to the introduction of the system, which makes the operation complicated and does not produce results. It seems that the challenge is to maximize the effect of system investment.

Solutions to challenges

It is a solution to “Information/Knowledge”.

To get information, you have to actively get it.

Recently, the number of business companies, IT vendors, and consulting companies that are actively working on DX is increasing. It is important to participate in seminars hosted by such companies and obtain information. One method is to hold a study group to share the acquired information within the company.

It is also important to invite external IT vendors into the company and obtain information on the spot. It is necessary to consider the solution that suits your company both as a whole and in parts.

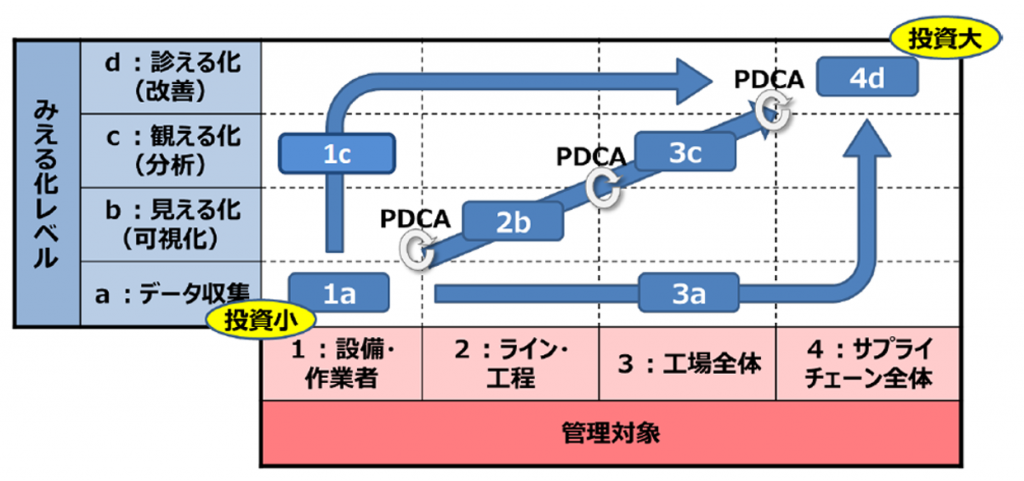

In order not to fail in DX in the manufacturing industry

and Thailand

出典: 製造業DX取組事例集|pwc

If you would like a collection of carefully

selected introduction case studies,After submitting the form, the PDF file

We will send you a download link.

_Required_ _Company

_Required_ _Department

_Required_ _Name

_Required_ _Address

_Required_ _Phone

_Required_ _E-mail

_Required_ _Inquiry