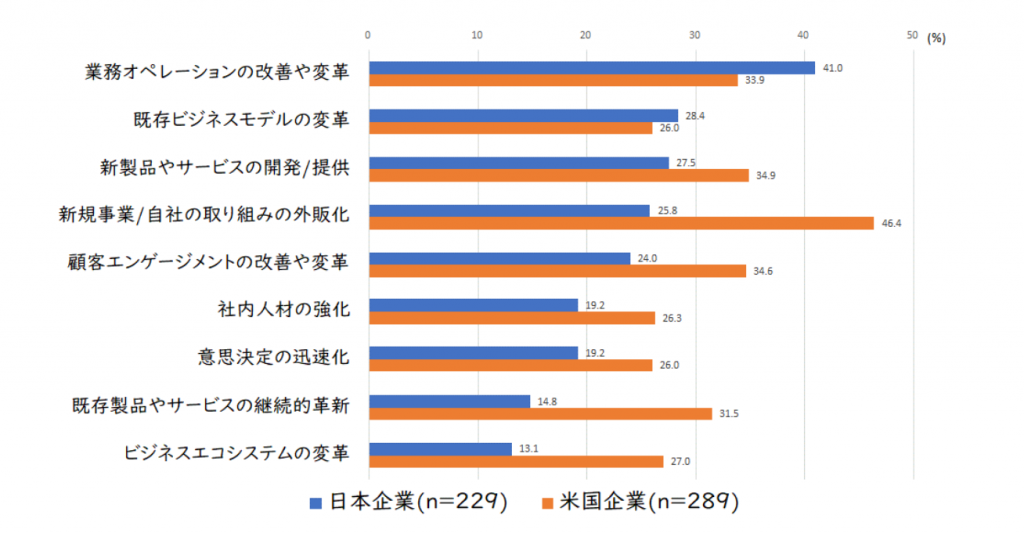

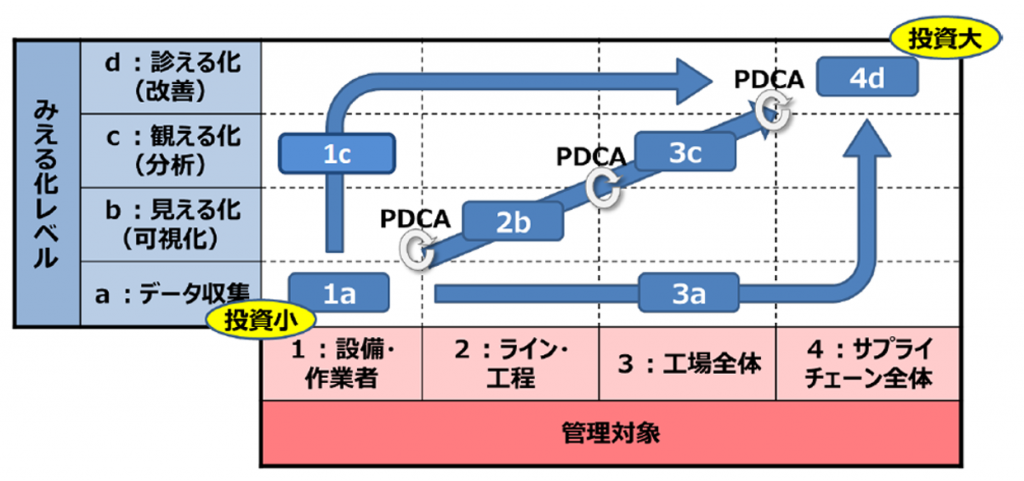

出典: 三菱UFJリサーチ&コンサルティング(株)

「我が国ものづくり産業の課題と対応の方向性に関する調査」(2019年12月)

What is the DX initiative in the manufacturing industry and Thailand? Commentary on issues and examples

![]() 15-Aug-2022

15-Aug-2022 ![]() 15-Aug-2022

15-Aug-2022

目次 ∇

1 What is DX?

2 DX in the manufacturing industry

2.1 What is DX in the manufacturing industry?

2.2 Challenges in manufacturing industry DX “2025” problem

2.3 Purpose of Manufacturing DX

2.4 Manufacturing industry DX utilization case

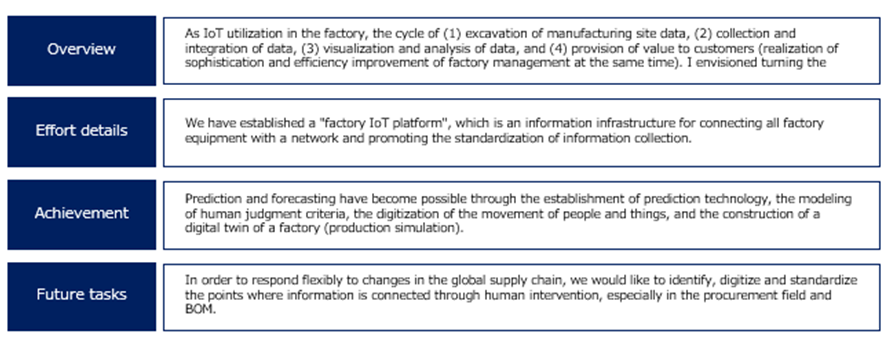

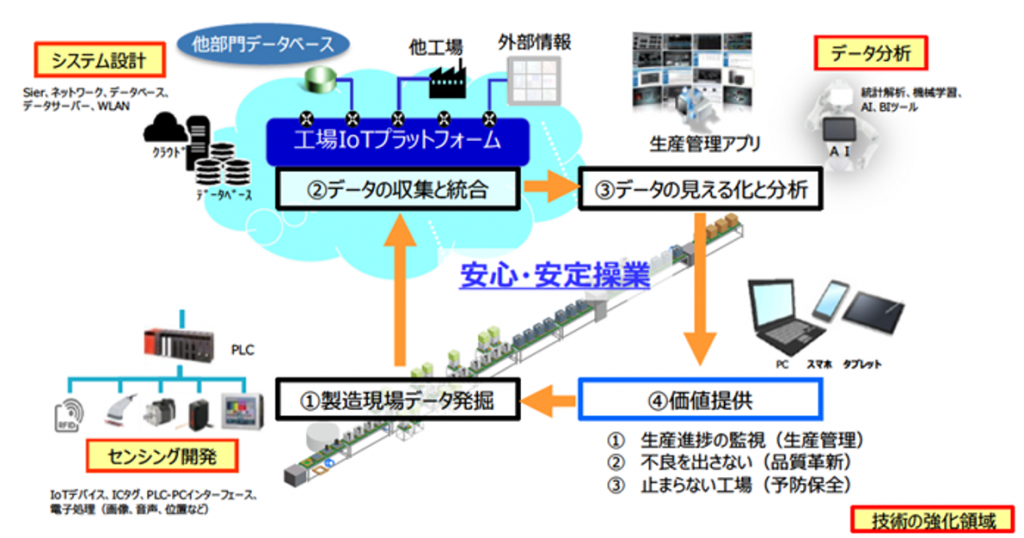

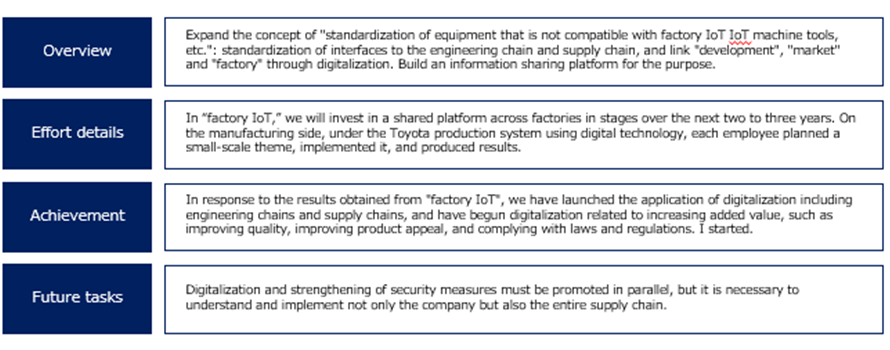

2.4.1 Case① Toyota Motor Corporation “Factory IoT“

2.4.2 Case② Daikin Industries, Ltd. “Factory IoT Platform“

3 DX situation in Thailand

3.1 Role of the Ministry of Digital Economy and Society

3.2 Structure of the Ministry of Digital Economy and Society

3.3 DX startup company investment by Digital Economy Promotion Organization

3.4 Examples of investments in DX startup companies

3.4.1 Case study① Thailand’s first car sharing service startup

3.4.2 Case study② Logistics efficiency digital service

3.4.3 Case study③ Energy saving system with DX

4 Summary: DX initiatives in the manufacturing industry and Thailand

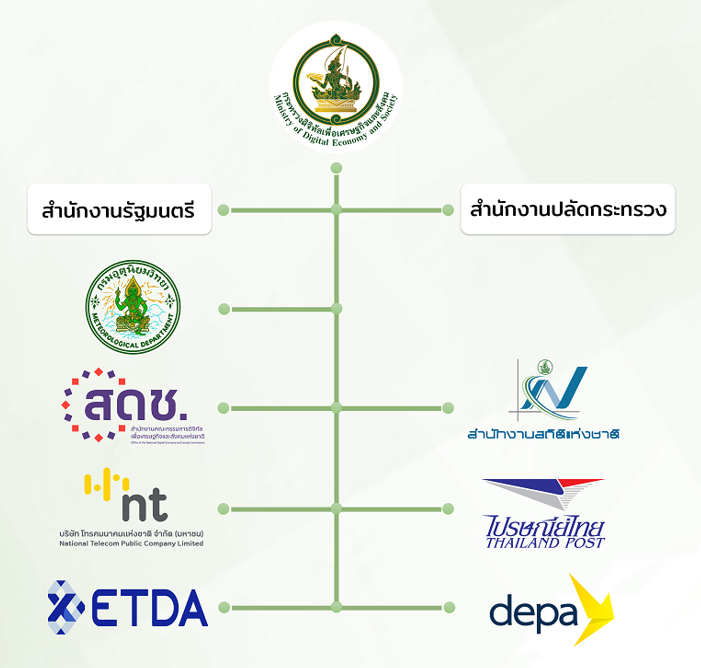

出典:デジタル経済社会省

The Ministry of Digital Economy and Society is accompanied by four public bodies and state-owned enterprises.

1. National Telecommunications Public Company Limited (บริษัท โทรคมนาคมแห่งชาติ จำกัด )

2. Thai Post Co., Ltd. (บริษัท ไปรษณีย์ไทย จำกัด)

3. Digital Economy Promotion Organization (สำนักงานส่งเสริมเศรษฐกิจดิจิทัล)

4. Electronic Transaction Development Agency (สำนักงานพัฒนาธุรกรรมทางอิเล็กทรอนิกส์)

出典:デジタル省構図

Digital Economy Promotion Agency Commonly known as: I would like to introduce an example of what kind of companies depa invests in.

出典:Haupcar

Company name:

Haupcar (บริษัท ฮ้อปคาร์ จำกัด)

Business description:

Hopcar is Thailand’s first car sharing service startup.

24 hours a day through an application to book a car dispatch, open and lock the car,

“Can be used by the hour without paying daily.”

Website:

http://www.haupcar.com/

出典: Logisty

Company name:

Logisty (บริษัท โลจิสตี จำกัด)

Business description:

“Logistics” connects transportation service providers and exchanges jobs and vehicles

A platform that maximizes profits.

Improve customer service and reduce car idle problems.

Website:

http://www.haupcar.com/

出典: ENRES

Company name:

ENRES (Energy Response Company Limited) (บริษัท เอ็นเนอร์จี้ เรสปอนส์ จำกัด)

Business description:

The management of commercial buildings and factories consists of multiple systems.

In order to further improve the management efficiency of commercial buildings and factories, ENRES will utilize IoT technology to

Introduce sensors and control systems.

Artificial intelligence technology AI is used to collect the large amount of data received from all sensors

processing to achieve the most efficient control and minimize power consumption

It will be possible. “This will further reduce energy consumption.”

Compatible with smart cities by controlling electrical systems in districts and cities

Reduce peaks and electricity consumption across the city.

Website:

http://www.haupcar.com/

出典: 製造業DX取組事例集|pwc

If you would like a collection of carefully

selected introduction case studies,After submitting the form, the PDF file

We will send you a download link.

_Required_ _Company

_Required_ _Department

_Required_ _Name

_Required_ _Address

_Required_ _Phone

_Required_ _E-mail

_Required_ _Inquiry